Forklifts are indispensable workhorses in warehouses and industrial settings, but like any machinery, they can encounter problems that affect their performance and safety. In this guide, we'll explore the top 10 common forklift problems and how to address them.

Let's get into it.

Diagnosing the Problem

1. Tire Troubles

Forklift tires endure heavy loads and rough terrain, making them prone to wear and tear. Common issues include worn treads, punctures, and damage from debris.

Allowing your tires to be worn down too much poses a significant risk to operators and others working in lumber yards and warehouses.

By performing routine maintenance and checks, you can replace damaged tires and maintain stability and performance in your work environment.

2. Battery Problems

Like automobiles, most forklifts are battery-powered. Over time, batteries degrade and need to be replaced, decreasing power and reducing run times.

Regular battery maintenance, including proper charging and watering, can extend battery life. If a battery becomes faulty or fails to hold a charge, replacement is needed.

3. Hydraulic Leaks

The hydraulic system is crucial for lifting and lowering loads. Hydraulic leaks can occur due to worn seals, damaged hoses, or loose fittings. These leaks not only reduce lifting capacity but also pose safety risks.

Photo by: OSHA Safety Manual

4. Brake Malfunctions

Brakes are critical for safe operation, but they can experience wear and tear over time. Common brake issues include worn brake pads, brake fluid leaks, and malfunctioning brake systems.

Performing continual brake maintenance, including replacing worn parts and adjusting the brake system, is essential for reliable stopping power and safety.

5. Engine Troubles

A forklift's engine powers its movement and operations. Engine problems manifest as starting issues, unusual noises, or poor performance. Regular engine maintenance, including oil changes, filter replacements, and tune-ups, can prevent common engine problems and ensure smooth operation.

6. Steering Difficulties

Faulty steering systems can affect a forklift's maneuverability and control, posing substantial safety risks.

Steering problems may result from loose steering components, worn steering mechanisms, or hydraulic problems. Prompt diagnosis and repair of steering issues are crucial to maintaining safe operation.

Photo by: First Quality Forklift Training LLC

7. Electrical Faults

Forklifts rely on electrical components, including lights, controls, and safety features.

Electrical faults, such as blown fuses, corroded wiring, or malfunctioning switches, can disrupt operation. Checking your electrical components regularly should be on your maintenance list to avoid massive downtime.

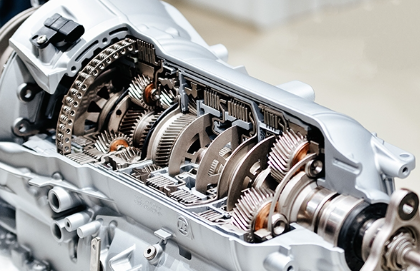

8. Transmission Problem

The transmission is responsible for shifting gears and transferring power from the engine to the wheels.

Transmission problems can manifest as slipping gears, difficulty shifting gears, or transmission fluid leaks. Regular inspection and maintenance of the transmission—including checking fluid levels and replacing worn parts—is essential to prevent transmission problems.

9. Cooling System Failures

The cooling system helps regulate the engine's temperature and prevent overheating. Cooling system failures, such as coolant leaks or radiator damage, can damage the engine and cause even more performance issues.

You will need to check the coolant levels and repair leaks occasionally to keep your forklift up and running.

10. Mast Issues

The mast is responsible for lifting and lowering loads, making it a critical forklift component. Mast issues—such as sticking, uneven lifting, or hydraulic problems—can affect load handling and pose safety risks.

You can attend to the mast by lubricating moving parts and inspecting hydraulic cylinders.

Routine Maintenance

By understanding and addressing these common forklift problems through regular maintenance and repairs, you can increase the smooth and safe operation of your forklift fleet.

Remember to prioritize safety and invest in proper training for operators to minimize the risk of accidents and injuries in the workplace. For even more protection, shop our forklift enclosures.

With proactive maintenance and diligent troubleshooting, you can maximize the efficiency and longevity of your forklifts, keeping your operations running how they should.

Leave a comment